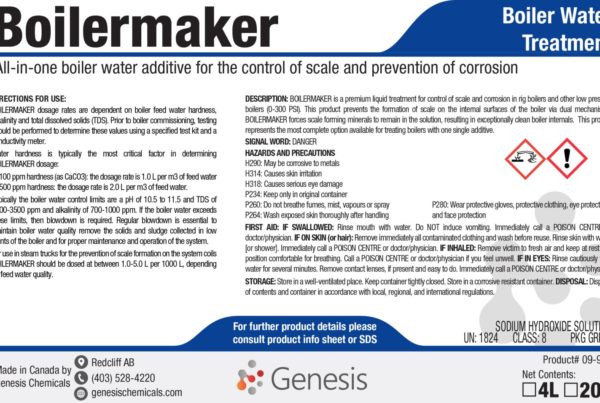

Boilermaker is a premium all-in-one boiler water corrosion and scale control liquid treatment for control of scale and corrosion in rig boilers and other low-pressure boilers (0-300 psi). This product prevents the formation of scale on the internal surfaces of the boiler via dual mechanisms.

Boilermaker forces scale forming minerals to remain in the solution and unable to deposit as scale. If any minerals were to “sneak past” the primary mechanism of solubilization, this product retains the ability to precipitate the excess minerals and produce a non-adherent sludge. This sludge is easily removed by following a regular blowdown schedule.

Utilizing Boilermaker to treat your boiler water will result in little to no sludge buildup within the system. This eliminates the potential of solids and sludge to collect at low points which can then result in the need of additional maintenance.

There truly is no treatment option for boiler water that is more complete, than Boilermaker.

Product Features

- Relatively low solids formulation, This allows for additional cycles of concentration compared to competitive treatment options and reduces the amount of blowdown required, resulting in a reduction in the consumption of water as well as treatment chemical.

- Effectively treats water from all local raw water sources (even water of high hardness). Providing effective control of scale and helps prevent corrosion

- Contains oxygen neutralizing components to reduce corrosion potential from dissolved gases (O2 and CO2)

- Utilizes modern, efficient boiler treatment chemistry.

- Maintains a clean system, improves boiler efficiency and prevents failures

- Contains neutralizing amines to reduce corrosion potential in condensate

Applications Include

- Oilfield steam boilers (Rig Boilers)

- Steam & Vac trucks

- Any boiler water treatment needs

*Oilfield Steam Boilers (Rig Boilers) are often fed with raw untreated water from the nearest water source, be it a drainage pond, slough, lake or other untreated supply. This water often contains a high concentration of scale forming minerals which can impair the operation of the boiler reducing its efficiency and shortening its lifespan. Rig Boilers are critical to ensure reliable and efficient supply of heat for the crew, drilling and safety equipment. As such, it is important that they be properly maintained. This begins with adequate feed water chemical treatment to control scale and corrosion and keep the boiler operating reliably and efficiently.

**Your Genesis sales Representative can show you how to properly test the boiler water and interpret the results to properly control the water chemistry in your boiler.

Available Packaging

20L Carboy

205L Drum